Sales of VAUTID wear plates which is the product of German VAUTID GmbH that DOKA is the distributor , production of ready to install construction made of VAUTID plates and production of formed plates are our one of the most important main activities in wear branch.

The main headers of this page content is as follows.

|

|

Doka Vautid brochure (Wear solutions) |

|

||

|

|

Vautid wearplates brochure |

|

| Standard plates | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

The most used standard dimensions and thicknesses (base material + hardfacing):

Base materials:

| |||||||||||||||||||||||||||

| Highlights of VAUTID Wear Plates | |

|---|---|

|

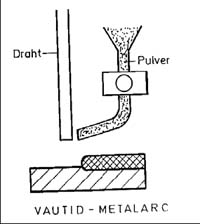

A - METAL-ARC-PROCESS

The most important feature of VAUTID wear plates (VVP) which makes it unique is “metal-arc-process”. This very special production technique which is applied by VAUTID only among the competitors , provides many advantages like minimum dilution of hardfaced layer in to the base material , much more primary carbides and hardness , excellent constancy of thicknesses of both deposit layer&base material comparing the other conventional methods.

|

|

|

B - QUALITY CONTROL

All VAUTID wear plates are manufactured according to DIN ISO 9001. Raw materials are accepted only from especially qualified and approved suppliers. A rigid control of all materials delivered to VAUTID is the basis of a very narrow production tolerances. An analysis is made in VAUTID’s special laboratory for composition, grain size as well as bulk density. The microstructure and chemical composition of the hardfacing is analyzed according to a fixed random-test plan. All production is made after these analyses within the narrow VAUTID tolerances. Finished products are checked for straightness and thickness. In some special applications (like fan blades) the plates can be tested with ultrasonic waves to check the crack status.

|

|

| Wear plate types | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application examples |

|---|

|

Cement plants

Steel industry

Coal Power Plants

Other application examples

|